Winmate 4K Ultra-High Definition Military Monitors

- 4K sharp and detailed image, 10-bit colour with over 1.07 billion variations

- Simultaneous PIP, PBP and POP

- Light sensors for effective automatic display brightness and stabilises luminance

- Optically bonded

- 178°/178° wide viewing angle for maximum visual performance

- IP66-certified

- MIL-STD-810G environmental and MIL-STD-461F EMC standards

- Capacitive touch keys

Winmate Communications, a global leader in advanced, rugged mobile technologies, offers ultra-high definition (UHD) military monitors that feature pristine image quality of up to 4K resolution at 1080p. The Winmate 4K military monitors show sharp and detailed images, allowing simultaneous viewing Picture-In-Picture (PIP), Picture-by-Picture (PBP) and Picture-Over-Picture (POP).

The 4K military displays offer 10-bit colour with over 1.07 billion variations, with a 14-bit look-up table (LUT) included that enables rendering of surgical images and offers 256 of the most appropriate tones. An ambient light sensor adjusts the display’s brightness automatically when moving from one lighting condition to another, or if the ambient light suddenly increases or decreases.

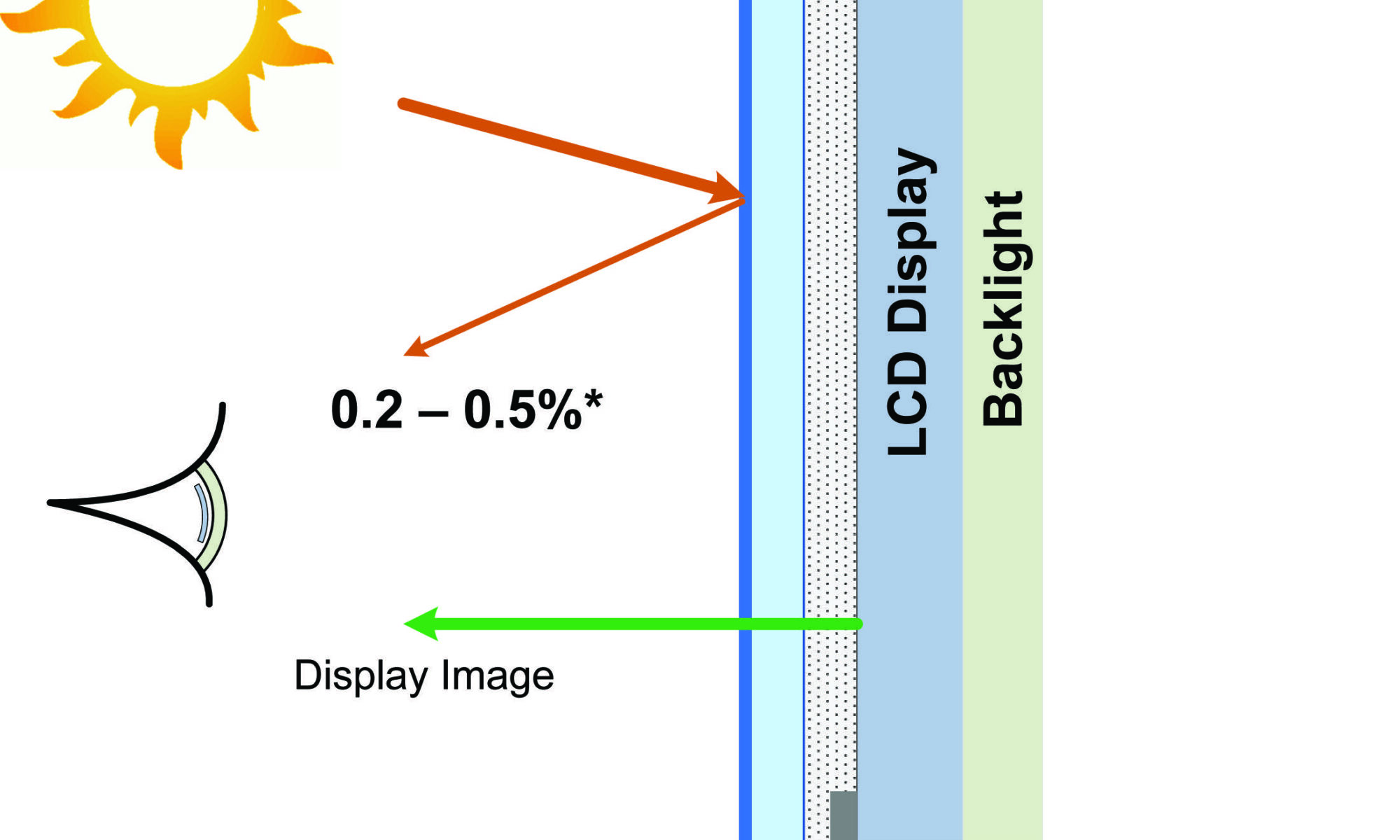

All Winmate military displays are optically bonded for maximum visual performance and allow users to see accurate images from all views from their 178°/178° wide viewing angle. 3D LUT technology is featured to correct non-linear colour rendering errors which are common in LCD displays. The backlight sensor stabilises brightness/luminance output and provides the user with a consistent image.

The Winmate 4K military monitors are IP66-certified, giving complete protection against contact from dust and powerful jets of water. Cleaning fluid build-up and corrosion are minimised with its sealed case and fanless design. Displays are enhanced with edge-to-edge protective glass and its true flat sides provide protection by reducing any gaps to stop dust or liquid gathering.

Users can access information quickly through the capacitive touch keys, and an optional rubber bumper provides solid edge protection from accidental head injuries and other equipment damage.

Winmate 4K military monitors are built to survive drops, shocks, liquid spills, vibrations, dust, salt and extreme temperatures – they are designed and tested for MIL-STD-810G environmental and MIL-STD-461F EMC standards.

Please speak to our military display experts to find out more information about the Winmate 4K military monitor range.